Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The piston`s function is to act as a moveable plug in the cylinder, forming the bottom part of the combustion chamber. There`s a gas-tight seal between the piston and the cylinder wall - so the only way for the hot combustion gases to expand is by forcing the piston down. It`s the same principle behind a cannonball, but instead of flying off into someone`s beloved pirate ship, the piston is pushed back up the cylinder by the rotating Crankshaft and the cycle repeats itself.

Huge forces are generated during the change in direction of a piston on its up and down motion. A lighter piston assembly has less momentum, thus exerting less force and allowing higher RPM engines. This means that there`s a constant push to reduce the weight of the connecting rod and piston.

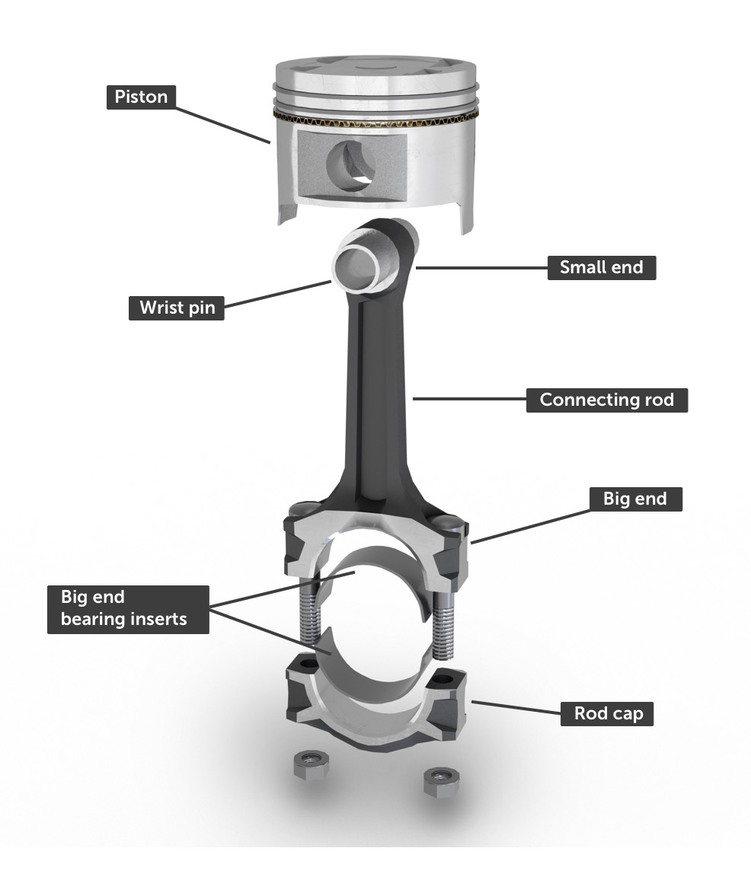

The piston is connected to the crankshaft through a connecting rod , often shortened to rod or conrod . These parts together are known as the piston assembly . Both ends of the connecting rod are free to pivot: The part of the connecting rod which connects to the piston is called the small end , and the end that attaches around the crankshaft is called the big end . The big end will have bearing inserts which minimise friction and maintain an exact oil clearance with the rod journal on the crankshaft. The connecting rod is split into two - with a rod cap being used to clamp around the big end bearing and crankshaft.

Piston assembly components

The power in an engine all comes from the force pushing on the top of the piston. That force is determined as the area of the piston multiplied by the gas pressure. Bigger pistons, and higher gas pressure will provide more power. On the whole, piston size is constrained by the design of the engine but the piston does have a vital role in maintaining high gas pressure by creating a gas-tight seal with the cylinder wall.

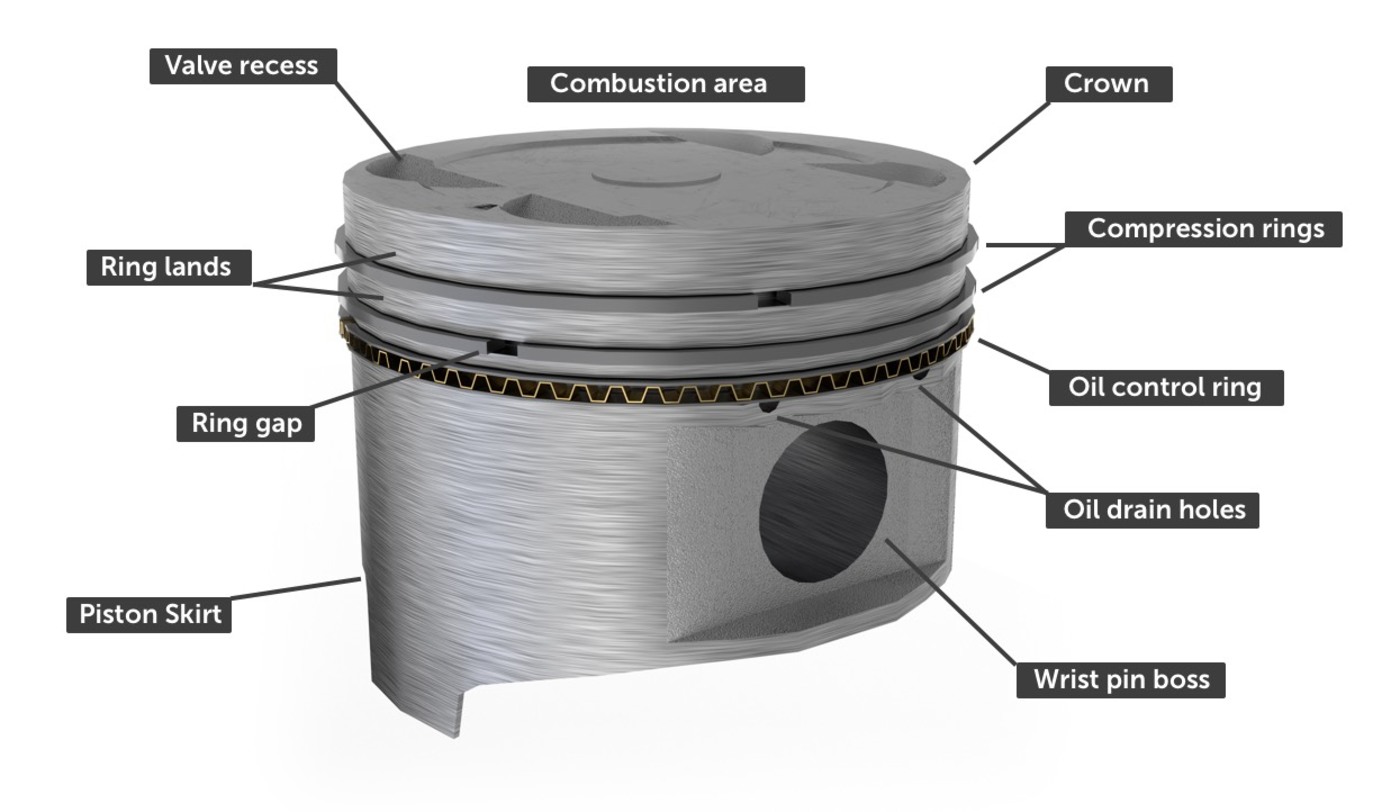

The top surface of the piston is called the crown (also head or dome ). There are various shapes of crown in production engines, but typically the crown will be flat, domed or dished.

[Various crown shapes]

Almost all modern pistons include valve reliefs which provide a clearance around the valves at the top of the piston stroke.

The crown, being the area directly in contact with the hot combustion gases, gets extremely hot. It is this area that expands the most and so there will be a slight taper inwards from the bottom of the piston to allow a greater clearance around this top land between the crown and top Piston Ring.

While we want a gas-tight seal, we also need the piston to run smoothly along the cylinder with minimal friction, so the piston needs some clearance . A typical piston will have a clearance of 0.1mm (0.004") between itself and the cylinder wall - that`s around the width of a human hair. To maintain this clearance, the piston must be precisely machined, and the alloy that it is made from will be exactly specified to account for thermal expansion.

The small gap between the piston and cylinder wall is bridged by the piston rings , which fit into grooves on the piston in an area known as the piston belt . The spaces between these grooves are called ring lands .

The piston is attached to the connecting rod by a short hollow tube called a wrist pin , or gudgeon pin . This wrist pin carries the full force of combustion.

The piston is not only subject to vertical forces during combustion, but also side forces caused by the continuously changing angle of the connecting rod. Because of these side forces, the piston needs smooth surfaces to run against the cylinder wall and keep the piston guided vertically upright. The side surfaces of a piston are known as the piston skirt .

[Full skirt vs slipper skirt]

There are two types of skirt. The most basic is a full skirt or solid skirt, which is the classic tubular shaped piston. This design is still used on truck and large commercial engines, but has long been replaced on cars and motorcycles by a lighter design known as a slipper piston .

The slipper piston has part of the skirt cut away, leaving only the surfaces that bear on the front and back of the cylinder wall. This removal minimizes weight and reduces the area of contact between the piston and cylinder wall, thus reducing friction.

The power in an engine all comes from the force pushing on the top of the piston. That force is determined as the area of the piston multiplied by the gas pressure. Bigger pistons, and higher gas pressure will provide more power. On the whole, piston size is constrained by the design of the engine but the piston does have a vital role in maintaining high gas pressure by creating a gas-tight seal with the cylinder wall.

The top surface of the piston is called the crown (also head or dome ). There are various shapes of crown in production engines, but typically the crown will be flat, domed or dished.

[Various crown shapes]

Almost all modern pistons include valve reliefs which provide a clearance around the valves at the top of the piston stroke.

The crown, being the area directly in contact with the hot combustion gases, gets extremely hot. It is this area that expands the most and so there will be a slight taper inwards from the bottom of the piston to allow a greater clearance around this top land between the crown and top piston ring.

While we want a gas-tight seal, we also need the piston to run smoothly along the cylinder with minimal friction, so the piston needs some clearance . A typical piston will have a clearance of 0.1mm (0.004") between itself and the cylinder wall - that`s around the width of a human hair. To maintain this clearance, the piston must be precisely machined, and the alloy that it is made from will be exactly specified to account for thermal expansion.

The small gap between the piston and cylinder wall is bridged by the piston rings , which fit into grooves on the piston in an area known as the piston belt . The spaces between these grooves are called ring lands .

The piston is attached to the connecting rod by a short hollow tube called a wrist pin , or gudgeon pin . This wrist pin carries the full force of combustion.

The piston is not only subject to vertical forces during combustion, but also side forces caused by the continuously changing angle of the connecting rod. Because of these side forces, the piston needs smooth surfaces to run against the cylinder wall and keep the piston guided vertically upright. The side surfaces of a piston are known as the piston skirt .

[Full skirt vs slipper skirt]

There are two types of skirt. The most basic is a full skirt or solid skirt, which is the classic tubular shaped piston. This design is still used on truck and large commercial engines, but has long been replaced on cars and motorcycles by a lighter design known as a slipper piston .

The slipper piston has part of the skirt cut away, leaving only the surfaces that bear on the front and back of the cylinder wall. This removal minimizes weight and reduces the area of contact between the piston and cylinder wall, thus reducing friction.

The power in an engine all comes from the force pushing on the top of the piston. That force is determined as the area of the piston multiplied by the gas pressure. Bigger pistons, and higher gas pressure will provide more power. On the whole, piston size is constrained by the design of the engine but the piston does have a vital role in maintaining high gas pressure by creating a gas-tight seal with the cylinder wall.

The top surface of the piston is called the crown (also head or dome ). There are various shapes of crown in production engines, but typically the crown will be flat, domed or dished.

[Various crown shapes]

Almost all modern pistons include valve reliefs which provide a clearance around the valves at the top of the piston stroke.

The crown, being the area directly in contact with the hot combustion gases, gets extremely hot. It is this area that expands the most and so there will be a slight taper inwards from the bottom of the piston to allow a greater clearance around this top land between the crown and top piston ring.

While we want a gas-tight seal, we also need the piston to run smoothly along the cylinder with minimal friction, so the piston needs some clearance . A typical piston will have a clearance of 0.1mm (0.004") between itself and the cylinder wall - that`s around the width of a human hair. To maintain this clearance, the piston must be precisely machined, and the alloy that it is made from will be exactly specified to account for thermal expansion.

The small gap between the piston and cylinder wall is bridged by the piston rings , which fit into grooves on the piston in an area known as the piston belt . The spaces between these grooves are called ring lands .

The piston is attached to the connecting rod by a short hollow tube called a wrist pin , or gudgeon pin . This wrist pin carries the full force of combustion.

The piston is not only subject to vertical forces during combustion, but also side forces caused by the continuously changing angle of the connecting rod. Because of these side forces, the piston needs smooth surfaces to run against the cylinder wall and keep the piston guided vertically upright. The side surfaces of a piston are known as the piston skirt .

[Full skirt vs slipper skirt]

There are two types of skirt. The most basic is a full skirt or solid skirt, which is the classic tubular shaped piston. This design is still used on truck and large commercial engines, but has long been replaced on cars and motorcycles by a lighter design known as a slipper piston .

The slipper piston has part of the skirt cut away, leaving only the surfaces that bear on the front and back of the cylinder wall. This removal minimizes weight and reduces the area of contact between the piston and cylinder wall, thus reducing friction.

LET'S GET IN TOUCH

Copyright © 2024 1D auto parts All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.